Kumaş Kesim Optimizasyonu

In the second stage, the optimization parameters of the balls to be cut in line with customer requests are entered into the system once. Thus, the system automatically uses these parameters in all optimizations made for that customer.

When the optimization is run according to these parameters, the most suitable cutting points are determined by the system so that the highest A quality and the lowest wastage occur as follows.

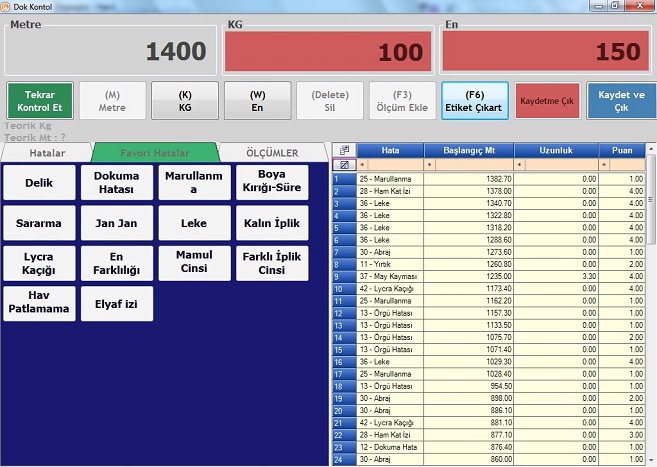

All balls belonging to the resulting plan and errors in the balls can be reported on the system.

Workload Analysis

The balls are cut according to the optimization plan created as the third and final stage. Again, the barcode label can be printed, which can be customized according to customer requests.